“If you work just for money, you’ll never make it, but if you love what you’re doing and you

Ray Kroc, McDonald’s Founder

always put the customer first, success will be yours.”

Introduction

I am old enough to remember when McDonald’s restaurants were scarce. Where I grew up in Central Connecticut, I could recall only one McDonald’s franchise located just 10 miles away from our home. My Father took us there about twice a year, and when he did, I felt as if I had died and gone to heaven. McDonald’s hamburgers were the finest thing I have ever tasted. Eating one today brings back those memories of the spiritual bliss I experienced in the back seat of my Father’s turquoise, wood-paneled Mercury station wagon. And those fries and shakes? I digress…

I am still a fan of McDonald’s. However, after over three decades of a career in Lean management, I view them, like many things, differently. Looking at a McDonald’s operation through a Lean lens is quite different than through the eyes of a child. This paper is not intended to disparage McDonald’s in any way. They are still one of the most successful franchises in American history, and I am still a loyal customer. One can apply this message I am about to convey to many other fast-food restaurants. I am using McDonald’s as my guinea pig, so to speak, because of my familiarity and affection for the Golden Arches.

Did McDonald’s Prioritize Cost over Service?

In the “old days,” a customer would walk up to a McDonald’s counter, order their product, pay the cashier, and almost immediately walk away with their order. Why was this? If you’re able to recall, McDonald’s would hold a “supermarket” of hamburgers, cheeseburgers, Big Macs, etc., so that your product was available at the point of purchase. Yes, their “make-to-stock” (MTS) approach necessitated carrying inventory to serve their customer better. However, those were simpler times when there were only a few products. Today, McDonald’s marketing wizards are creating an increasingly complex product menu that complicates any prebuild of inventory during peak times.

This illustration from McDonald’s current website boasts 11 different types of hamburgers. Ray Kroc’s vision of simplicity must have him rolling over in his grave. (I had sometimes wondered what Ray Kroc would have thought when McDonald’s rolled out its McRib® and lobster sandwiches.)

When McDonald’s held finished inventory, it had a shelf life and needed to be disposed of after a predetermined time period. I still remember our midnight visits to a local McDonald’s during high school. Our friends who worked there would hold any excess food for us that would have otherwise been thrown away. We enjoyed many a midnight snack, but times were much simpler then, and I cannot envision this era of “American Graffiti” happening today.

McDonald’s has completely transitioned to a “make-to-order” (MTO) assembly line. In doing so, McDonald’s missed many of the basic tenants of Lean, resulting in excessive wait times for their customers. Instead of paying the cashier and walking away with your order, you are given a ticket with an order number. You are then told to stand in a designated area and WAIT (translation: waste, lead-time) with other customers for your order. Is this the new definition of “fast” food? Has McDonald’s prioritized COST over SERVICE?

One could argue that product complexity was the driving force behind McDonald’s make-to-order transition. It is reasonable to assume that the ever-increasing product line expansion had a direct, negative impact on the cost of disposing of inventory due to spoilage. I have long suspected that this move was inspired by the finance and accounting arm of McDonald’s as they tallied up the cost of the disposed product which exceeded its shelf life. My suspicion was later confirmed by a senior Lean executive at McDonald’s, who suggested that McDonald’s has developed an ever-increasing, maniacal focus on cost reduction. I also learned that the Lean Office of McDonald’s reported to the Treasurer, who reported to the Chief Financial Officer. In my three decades of Lean management, this is the first time I have seen such a reporting relationship for a Lean Office.

Let’s examine how the adherence to Lean Basics would have made McDonald’s transition to a “make-to-order” environment more successful.

Lean Basics – Lean Principles That Were Ignored

- Safety-Quality-Delivery-Cost (SQDC)

SQDC is a hierarchy where Safety is always the number one priority. Next comes Quality, followed by Delivery (Service), and finally, Cost. The SQDC principle suggests that you would never compromise a higher-prioritized objective for one lower on the hierarchy. In fact, if you get the first three right (SQD), C takes care of itself. Have the accountants at McDonald’s prioritized Cost over Delivery and Service? I will leave that up to you to decide. - Cell Design Basics

As I have observed many McDonald’s food preparation kitchens around the country, I have noticed limited space necessary to flex labor up and down during varying demand periods. With their current setup, it is extremely difficult to distribute work segments and load operators properly to TAKT Time (more later). Although there appears to be subassemblies premade (hamburger patties, buns, etc.), the need to heat these items before they are prepared still exists in many cases, which I suspect compromises the quality of the product. This process step creates waiting time for the operator, which translates directly to the customer wait time. There also seems to be excessive, wasteful motion as food preparers reach for various condiments, packaging, and other necessary ingredients and utensils. We will discover later that this constricting configuration and the lack of Standard Work basics are the main culprits of customer wait time. - Standard Work

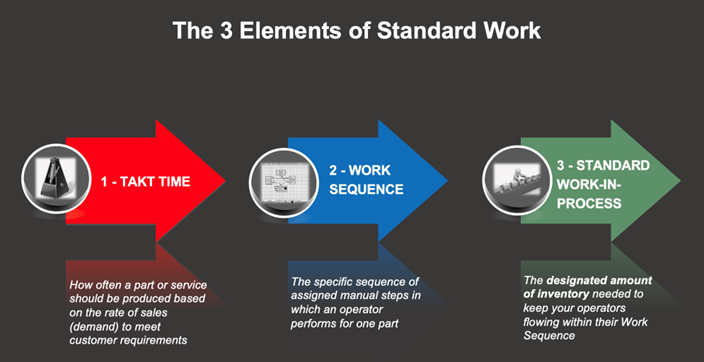

Standard Work (SW) is a way to document the “one best way” to do a particular job or operation. SW is what sheet music is to an orchestra. Knowing that any process is not perfect, SW provides a means to measure ourselves against a standard. Any deviations to the standard will promote Kaizen activity to ensure that the standard is met consistently. The three components of SW can be described in the following chart:

TAKT Time is based on the relative demand over a given time period and represents how frequently a product or service must be produced to meet customer demand for that relative time period. All industries have seasonal demand, whether quarterly, monthly, or weekly. In the fast-food industry, the demand fluctuates daily as well as within the day itself. For example, the demand for a fast-food restaurant is quite different at noon than it is at 10PM in the evening.

Using data for illustration purposes only, TAKT Time is calculated as follows for a Mcdonald’s operation:

TAKT Time = Time Available/Demand in units for Sandwiches

To calculate the TAKT Time for McDonald’s busy period (assume that the busy period for Mcdonald’s is from 11 AM to 2 PM, or 180 minutes), and the demand for sandwiches during this time period is 450 sandwiches. The TAKT Time would be calculated as follows:

TAKT Time = 180 Minutes (10,800 seconds)/450 Sandwiches = 24 Seconds

This means that McDonald’s needs to produce one sandwich every 24 seconds during this time period if they are to meet customer demand without excessive wait time.

So, what does this mean for the manning requirements of their kitchen? Regardless of the time of day and relative demand, the McDonald’s kitchen appears to be manned with the exact same headcount. This may be a product of poor cell design where manning is difficult to flex due to space and design constraints.

Let’s assume that the total time it takes to produce one sandwich is 2 minutes (120 seconds). The total manning required in the kitchen during the time period of 11 AM to 2 PM is as follows:

Manning requirements are dictated by the relative TAKT Time using the following formula:

People = Total Operator Cycle Time to Produce One Sandwich*/TAKT Time

120 seconds/24 Seconds = 5 Operators

- For the purposes of simplicity, the treatment of sandwiches with varying cycle times is beyond the scope of this paper.

McDonald’s would require five operators in the kitchen during their busy period of 11 AM to 2 PM, and no operator should be assigned a work sequence greater than TAKT Time, that is, 24 seconds. This suggests that sandwiches need to be produced in a one-piece flow fashion where the work components of assembling one sandwich are divided between the five kitchen operators.

Given this simple example, demand may fluctuate within the given time period, which may drive excess labor, or a deficiency of labor to meet demand. Another factor to consider is the accuracy of predicting demand for a given time period. The treatment of this variation is beyond the scope of this paper. Nevertheless, this approach is designed to provide service in a “fast food” manner by reducing the wait time experienced by the customer.

But should all products be made in a MTO manner? Let’s explore this question in the next section.

- Production and Inventory Policy

Like many companies, McDonald’s made the classic mistake of treating 100% of their demand with one fulfillment (production) system. McDonald’s moved from a 100% MTS (Make-To-Stock) approach to a 100% MTO (Make-To-Order) system. I believe the correct approach combines the MTS and MTO methodologies, depending on the demand frequency of their various product offerings.

To explain the merit of this hybrid approach, I’d like to take you away from McDonald’s for a moment to a wheelchair manufacturing company that was one of my first clients at Lean Horizons Consulting, LLC.

This company made two types of wheelchairs, standard, and custom. A standard wheelchair is one that we all see in hospitals and airports. They are basic wheelchairs with no unique features or characteristics. For some strange reason, they all seem to be blue. Conversely, a custom wheelchair is specifically designed and manufactured for a specific individual based on a prescription written by a physical therapist. There are hundreds if not thousands of potential options in addition to the fact that these custom wheelchairs need to consider all of the physical characteristics of the individual patient. The client I worked for made the wheelchair for Christopher Reeves, who became famous for his movie role as Superman. If you recall, Reeves fell off a horse in 1995 and became permanently paralyzed. Reeves passed away in 2004 at the early age of 52 due to complications from medication related to his condition.

This particular client called me because they had trouble meeting demand, and their past-due backlog was increasing at an alarming rate. Standard (let’s call them Airport wheelchairs) and custom wheelchairs (let’s call them Superman wheelchairs) were being manufactured on the same production line. It was clear to them that Superman products were explicitly designed to order. Once a Superman wheelchair was manufactured, there would never be another one like it due to its unique attributes. However, there were only a few SKUs (stock-keeping units) for the Airport product line. Clearly, the manufacturing and inventory policy for both product families needed to be differentiated.

Instead of treating all Airport wheelchairs as a discrete order, I suggested that the assembly line for these products be arranged into its unique value stream. I also suggested a finished goods stocking policy where the “supermarket” of finished, Airport wheelchairs, would be replenished with a pull signal back to the final assembly within the Airport wheelchair value stream. This pull signal would initiate all other inventory requirements from the Kanbans of the paint, fabrication, and subassembly cells. It seemed odd to my client that a Lean consultant would suggest the establishment of a finished goods inventory for Airport wheelchairs. I was asked, “Why would you introduce this cost into the system?” I reminded them of the SQDC philosophy where inventory falls into the COST category, and that their lead-time to their customer (DELIVERY) would be greatly reduced. Remember, D should take priority over C. I also told them that their total inventory investment throughout their Airport Value Stream would be greatly reduced, and as their lead-times improve, the reliance on a finished goods inventory to meet timely delivery would be reduced proportionately.

The Superman value stream needed to be treated differently. A separate value stream was created for Superman products, separate from the Airport value stream. Due to their one-time uniqueness, it was impossible to create a Kanban for these custom-fabricated frames, colors, and unique subassemblies. We still wanted to maintain a “pull” production process, so we incorporated FIFO lanes between fabrication and paint and between paint and assembly. These FIFO lanes limited the amount of inventory to be produced at any given point in time. (Note: The use of FIFO lanes is largely misunderstood and misapplied in the Lean community and will be a subject for a future white paper and/or podcast.) Unlike the Airport products, the customer order was introduced at the value stream’s fabrication point (rather than final assembly). The Superman wheelchair gained its identity at this point.

By creating a hybrid manufacturing and inventory management process of MTO and MTS, the wheelchair company was more successful in meeting customer demand for their Airport and Superman orders.

So, what does this have to do with hamburgers?

McDonald’s needs to take this same approach; an MTS system for their most popular items (for example, hamburgers, cheeseburgers, etc.) or key components, such as the hamburger patty, buns, etc. Also, they need to institute a MTO system for their low-volume products (McRib®, Filet of Fish, etc.). Separating the assembly lines for the hi-volume (MTS) and low-volume (MTO) products will yield significant benefits. The Standard Work technique would then be applied separately to the MTO and MTS work cells. This approach would utilize labor more efficiently and reduce the complexity of making all products in the same work cell.

Summary

In pursuit of improvement and change, I have witnessed companies moving from one end of the proverbial bell curve to the other. For example, a new CEO might take his company from a totally centralized organization to one that is decentralized, all for the sake of change. McDonald’s did the same when they moved from an MTO environment to MTS. A hybrid approach is rarely considered.

My experience has proven time and time again that when a company has a strategy of profit maximization through a maniacal, singular focus on cost reduction, they get neither. When cost reduction is prioritized over all goals, the SQDC hierarchy manifests itself into a CCCC hierarchy, where quality and service are severely compromised and growth experiences atrophy.

Despite health considerations, I still love McDonald’s simply because their hamburgers, French fries, and milkshakes take me back to my childhood in the back of my dad’s station wagon. The question that needs to be answered by McDonald’s leadership is whether they are marching to Ray Kroc’s words as outlined at the beginning of this paper:

“If you work just for money, you’ll never make it, but if you love what you’re doing and you always put the customer first, success will be yours.”

Ray Kroc